OHSWA Recycling Center, Utica

OVERVIEW

MRF Background

The Authority operates a single stream processing system. The single stream processing system was constructed in 2011 and operation began in January of 2012. This took the place of the Authority’s previous dual stream processing system that was built in 1991. The Authority is currently accepting all recyclable items- paper, plastic, metal and glass- mixed together.

VIEW

Location

STEPS

Recycling Process

Once the trucks arrive, they are weighed at the facility to see how much the waste weighs with the recyclables. Then the recyclables (mixed, loose recyclables paper, plastic metal, glass, and Cardboard) are dumped onto the tipping floor by the trucks. A loader picks up the recyclables and loads them into a large drum container (Drum Feeder). The drum rotates and feeds the material over the first conveyor belt which brings the recyclables into the system. The drum feeder feeds the material on the conveyor evenly.

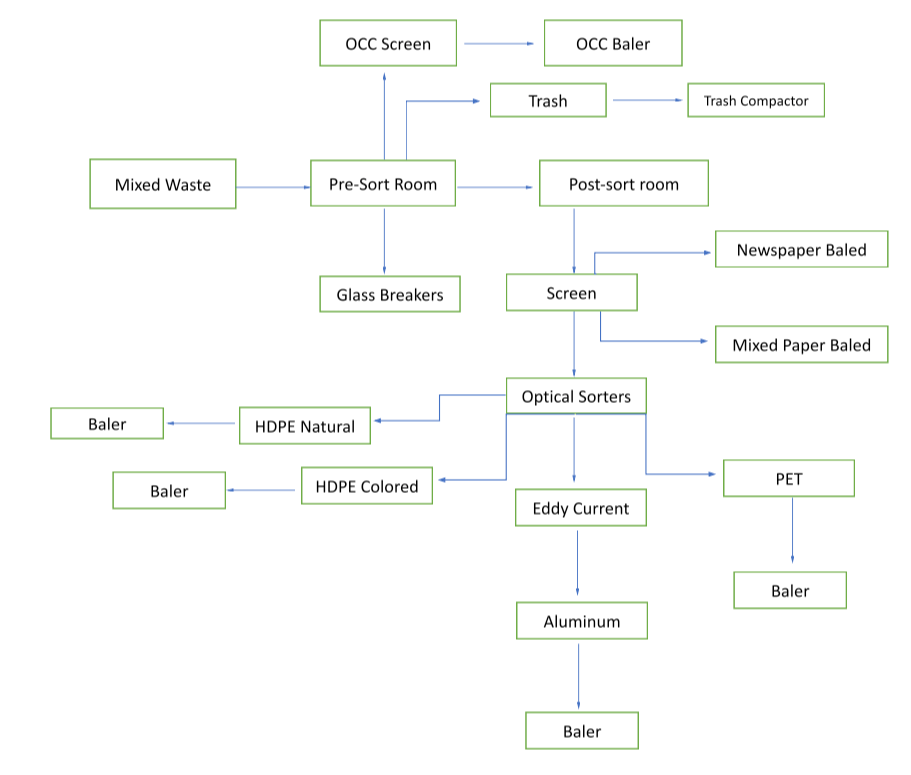

Pre-sort stage: The conveyor goes through the first room, called the presort room, where there are manual sorters who look for shredded paper that’s in plastic bags, or any trash that was placed in the recyclables and other types of film that need to be removed before they enter the single stream system. Once the material flows through the pre-sort, it drops down and hits the cardboards line. Then they go through another screening where there are large rotating disks, rotating at a fast speed. Here the material hits the rotating disks, the disks push the corrugated cardboard (OCC) over the top while all of the smaller pieces of paper and containers fall through. In this stage cardboard has been sorted out, and then only paper, mixed paper, containers and glass remains. These material goes up the conveyor and goes through the post sort and the manual sorters removes any OCC or trash that made it through the first screening stage. Once the material goes through the post sort phase, it enters the first glass breakers screens. As the disks are rotating the glasses break and fall underneath, whereas the paper is pushed over the top and containers falls through. The containers, plastic, metal, aluminum and glass are sorted out. The sorted paper after the screening moves down a conveyor and enters the sorting room. There are two conveyor belts in the sorting room and there are manual sorters that sort any garbage that may still be in the recyclables, and any cardboard or container that still has made it through. Once the paper goes through the sorting room, it goes through the balers.

Sorting plastics, metal and aluminum: The metal goes along the conveyor belt, and then a magnet pulls out metal, lids and any metallic containers, then these go up a conveyor where there are optical sorters. The sorters use infrared light technology to detect which type of plastic the container is. They look for PET plastic and HDPE natural plastic. The technology detects the type of plastic and then PET and HDPE are separated into its own container. PET, HDPE, and metal have now been sorted out and only 3-7 plastic and aluminum remain. These remaining materials come down a conveyor belt where there are manual sorters picking out different kinds of plastics. Now only residues which are non-recyclable items and aluminum are remaining. These materials then pass over a conveyor belt and with the help of Eddy current where the aluminum is repulsed and goes into its own container. The sorted materials are then moved through the conveyor belts into balers. The facility has two balers.