What Are MRFs?

OVERVIEW

EPA Waste Hierarchy

In the US, states and counties follow the Environment Protection Agency’s (EPA) waste management hierarchy of managing waste from the most environmentally sound option to the last one, starting with reduction at source, reusing resources, recycling materials, incineration

with energy recovery, and then landfilling as the lowest priority.[1]

MEANING

Defining MRF

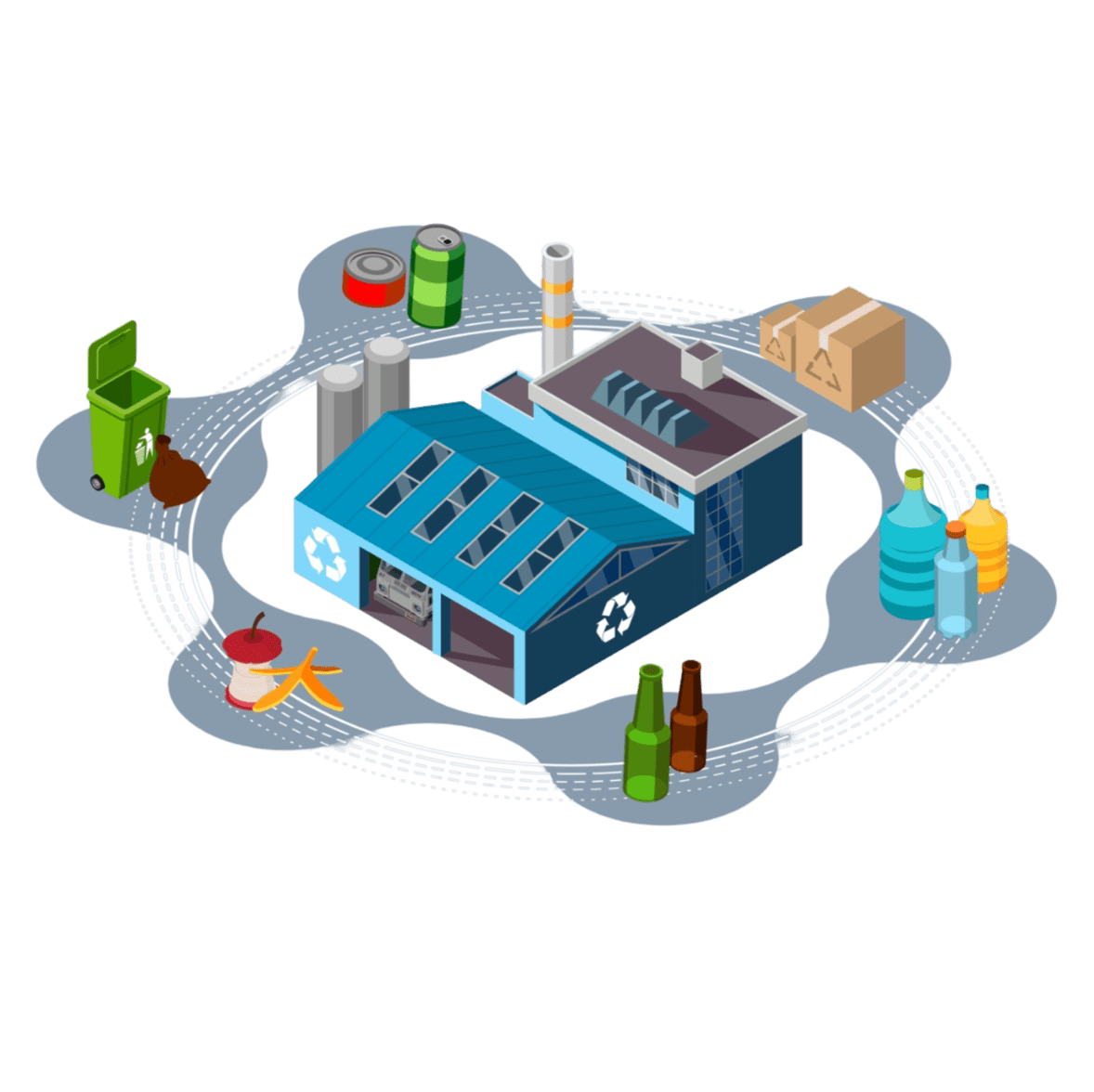

A Materials Recovery Facility (MRF), commonly known as a Material Recycling Facility. MRF is a plant that segregates recyclable materials using advanced machinery, the product is then sold to end buyers.[4,5] These MRFs sort a wide variety of recyclable materials such as, but not limited to, mixed paper, old newsprint (ONP), office paper, and old corrugated containers (OCC), plastics, aluminum/steel cans, glass bottles, etc.[6] MRFs combine mechanical and manual processes to segregate recyclable materials. Important design factors to maximize MRF efficiency include increased material flow rates, reduced residues, minimized human labor, increased labor safety, production of higher quality outputs, and minimized overall processing costs.[7]

PROCEDURE

How MRFs Work?

1

Collection & Transportation

Recyclable materials are collected and then delivered to the MRF.

Preliminary Sorting

Manual sorters remove large contaminants.

2

3

Automated Sorting

Mechanical systems like drum feeder, conveyor lines, air classification to segregate materials.

Magnetic Sorting & Eddy Currents

Separate ferrous and non-ferrous metals.

4

5

Optical Sorting

Identify and sort materials based on shape, size and color.

Baling

Sorted materials compacted and sent for remanufacturing.

6

VALUE

Benefits of MRFs

Diversion of Waste from Landfills

Waste diverted from incineration and landfills

Energy Saving

Recycling uses less energy in comparison to manufacturing new products from scratch.

Pollution Reduction

Reduces greenhouse gas emissions caused by improper disposal of waste

Employment Generation

Creates job opportunities in the recycling sector.

Promotes Sustainability

Supports a circular economy by reusing products rather than disposing them.

Supports Local Environmental Efforts

Creates environmental awareness and promotes responsible consumer practices.

References

- Manfredi, S., & Pant, R. (2013). Improving the environmental performance of bio-waste management with life cycle thinking (LCT) and life cycle assessment (LCA). International Journal of Life Cycle Assessment, 18(1), 285–291.

- Environmental Protection Agency (EPA). (2020). Advancing sustainable materials management: 2018 fact sheet assessing trends in materials generation and management in the United States.

- Van Ewijk, S., & Stegemann, J. A. (2016). Limitations of the waste hierarchy for achieving absolute reductions in material throughput. Journal of Cleaner Production, 132, 122–128.

- Pressley, P. N., Levis, J. W., Damgaard, A., Barlaz, M. A., & DeCarolis, J. F. (2015). Analysis of material recovery facilities for use in life-cycle assessment. Waste Management, 35, 307–317.

- Chertow, M., Reck, B. K., Wrzesniewski, A., & Calli, B. (2024). Outlook on the future role of robots and AI in material recovery facilities: Implications for U.S. recycling and the workforce. Journal of Cleaner Production, 470, 143234.

- Leahy, M. (2023, July 25). What is a materials recovery facility (MRF)? Rubicon. Retrieved from https://www.rubicon.com/blog/materials-recovery-facility/

- Kessler Consulting. (2009, September). Materials Recovery Facility Technology Review. Retrieved from https://www.nswai.org/docs/MATERIALS RECOVERY FACILITY TECHONOLOGY REVIEW.pdf

- www.freepik.com